Dynasafe’s Pyrolysis Destruction Chamber is available in different sizes, capacities, and implementations and can be customized even further with optional extra equipment and operations. Dynasafe’s Pyrolysis Destruction Chamber utilizes an indirectly heated pyrolysis system to safely decontaminates inert and combustible materials. The PDC is designed for the decontamination of materials such as personal protective equipment, soil, textiles, scrap, concrete, metal, and organics that have been exposed to bulk and trace explosives, propellants, or toxic substances such as dioxin-contaminated materials.

The batch-operated system is equipped with a loading tray to take bulk feed material as well as reusable loading baskets to facilitate the destruction process.

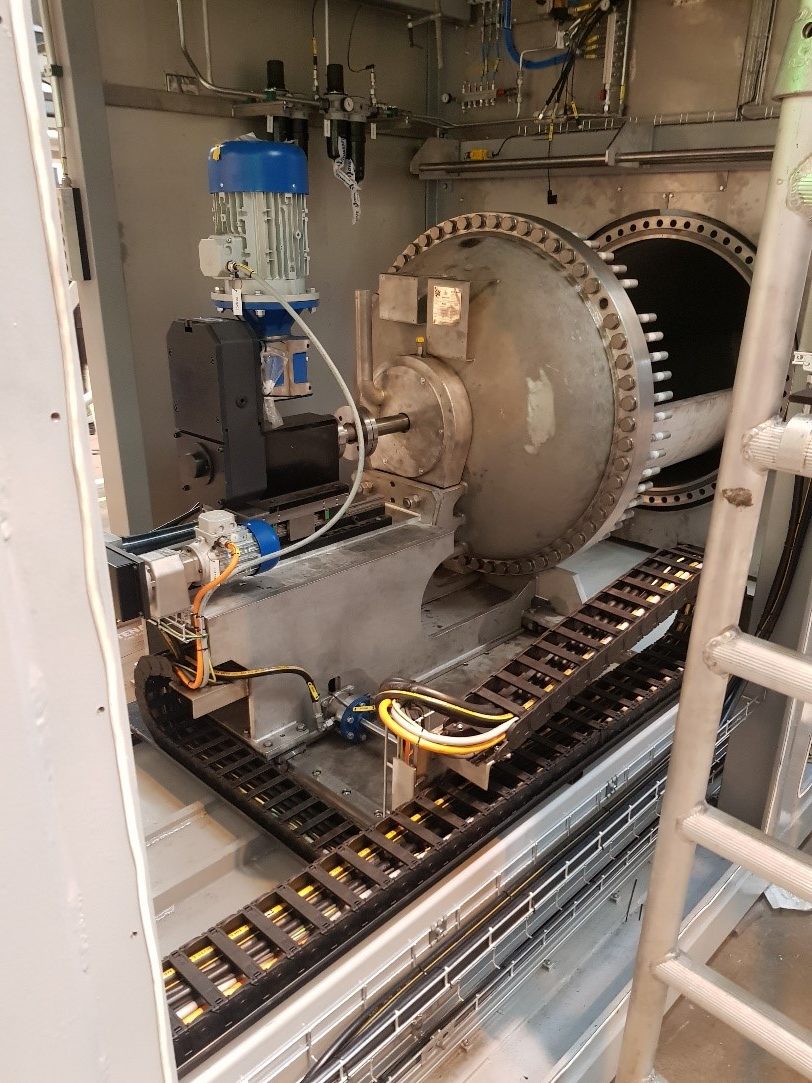

The PDC can be combined with an optional drilling unit to puncture and drain steel drums of toxic liquid for treatment to keep operators protected from contamination or exposure.