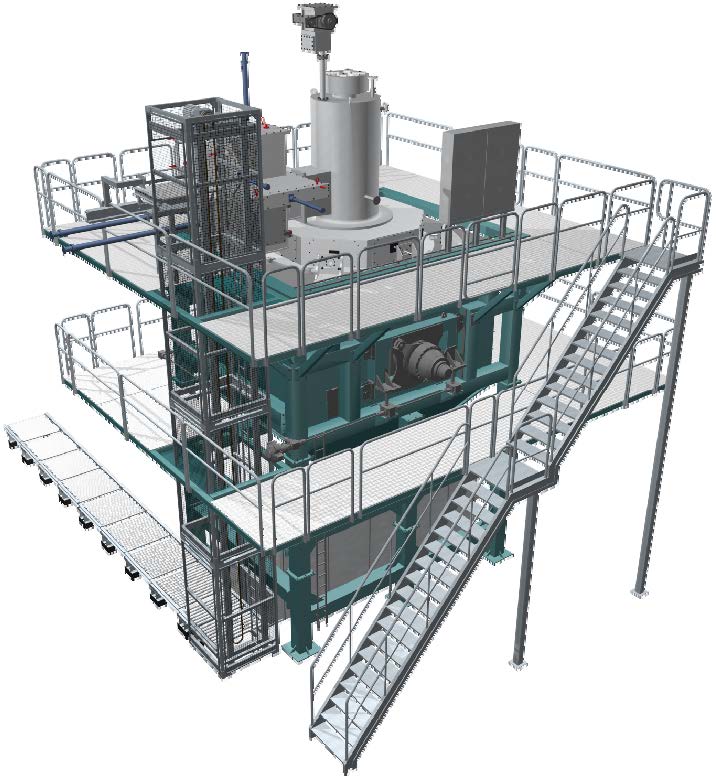

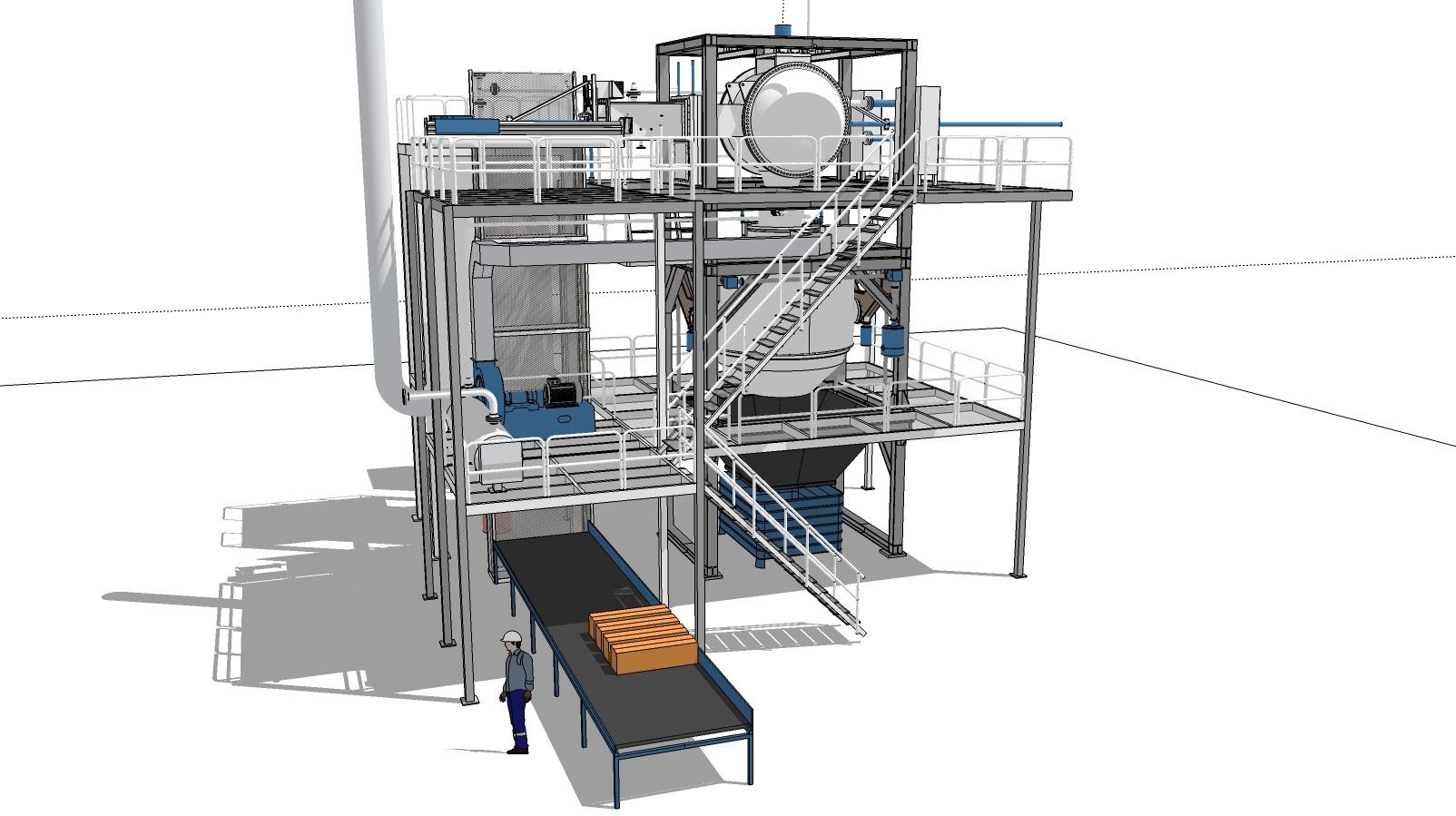

Dynasafe’s SDC systems are available in different sizes, capacities, and implementations and can be customized even further with optional extra equipment and operations. The SDC is equipped with an automated loading system that requires minimal human interaction. An operator puts the munitions on the processing line and does not touch it again until it is safely treated by the SDC.

An integrated control system allows operators to control and monitor the process from another room.

The SDC is a clean alternative to OB/OD that meets most environmental requirements. The resulting scrap metal is 3X decontaminated and able to be recycled.

The core of the SDC is an indirectly heated, armored chamber where munitions are heated until they burn, deflagrate, or detonate. The system is gas-tight, therefore the SDC is able to cope with aggressive materials as well toxic chemical agents. The system can withstand a detonation, though in most cases the munition undergoes deflagration, burning the munition so it is unsuitable for its original intended purpose. An internal fragment shield can be integrated to extend the lifetime of the detonation chamber.